The press brake has 3 control blocks. Two of them, with the middle plate filling valve, are straight mounted within the hydraulic cylinder to eliminate the need for piping involving the leading Handle block as well as the hydraulic cylinder.

The mechanical synchronization mechanism is created up of factors for instance torsion, swing arm, and joint bearings. It has a straightforward style, offers steady and reputable general performance, and features high synchronization precision.

As the founding father of MachineMFG, I have dedicated about a decade of my career to your metalworking field. My extensive knowledge has allowed me to be a professional in the fields of sheet metal fabrication, machining, mechanical engineering, and machine tools for metals.

Copper is actually a delicate substance and sheets are easy to bend. However, it needs careful dealing with and controlled force in order to avoid area damage or cracking. Furthermore, copper’s shiny aesthetic attractiveness can make it well known in electrical and numerous other purposes.

You can utilize a bending calculator obtainable on line to calculate the look variables and issues. We'll talk about these in more sections. Furthermore, you might want to specify the crystal clear Proportions and tolerances in the look. Step two: Planning Your File

This metal-forming method is appropriate for developing curvature styles from flat sheets. In the meantime, it's a lot of programs in tube shaping. You can get a lot more control around the procedure to keep up an exact and precise radius.

In the metalworking marketplace, a press brake is a sophisticated machine tool engineered specifically for bending sheet and plate materials, with sheet metal getting the predominant medium.

Metal Supermarkets is the globe’s largest modest-amount metal supplier with about a hundred twenty five brick-and-mortar suppliers through the US, copyright, and United Kingdom. We've been metal authorities and have already been providing high quality customer service and goods considering that 1985.

Understanding how you can bend sheet metal comes with an knowledge that aspects such as the thickness of the fabric, measurement on the bend, bend radius, and supposed purpose determine the procedures.

Often make use of a press brake where by applicable as it provides help and assures cleaner sheet metal bending and ongoing pattern across bent sheets.

The transformation occurs by using basic sheet-forming procedures for instance metal bending to condition the sheet metal into the specified varieties required for various manufacturing reasons. There are numerous processes involved with building this happen, and knowing ways to bend sheet metal comes with using a reasonable know-how about them.

Apparently, in contemporary sheet metal bending, the center English verb “breken” or “split” is utilized to seek advice from bending, altering path, or deflecting. Even a light-weight beam may be “damaged” by making use of a mirror.

Completely Welded Construction: The frame’s fully welded construction employs advanced welding techniques to offer Outstanding energy and rigidity, reducing deflection advanced hydraulic press brake below superior hundreds.

Some significant-end products even incorporate adaptive positioning algorithms that routinely regulate to part deformation through bending, maintaining optimum Speak to through the process.

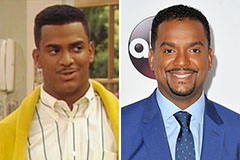

Alfonso Ribeiro Then & Now!

Alfonso Ribeiro Then & Now! Jonathan Lipnicki Then & Now!

Jonathan Lipnicki Then & Now! Destiny’s Child Then & Now!

Destiny’s Child Then & Now! Burke Ramsey Then & Now!

Burke Ramsey Then & Now! Mike Smith Then & Now!

Mike Smith Then & Now!